Smart Buildings Blog

The latest on all things commercial building automation, energy management, and IoT

What is Supply Air and Why is it Important to Monitor?

In an HVAC (Heating, Ventilation, and Air Conditioning) system, the supply air refers to the conditioned air provided to occupied spaces or zones within a building. The air is distributed from the HVAC system’s air handling unit (AHU) or fan coil unit (FCU) to provide heating, cooling, and ventilation.

Supply air is conditioned to meet the occupied spaces’ desired temperature, humidity, and air quality requirements. It is often treated by passing it through various HVAC system components, including filters, heating or cooling coils, humidifiers or dehumidifiers, and ventilation systems.

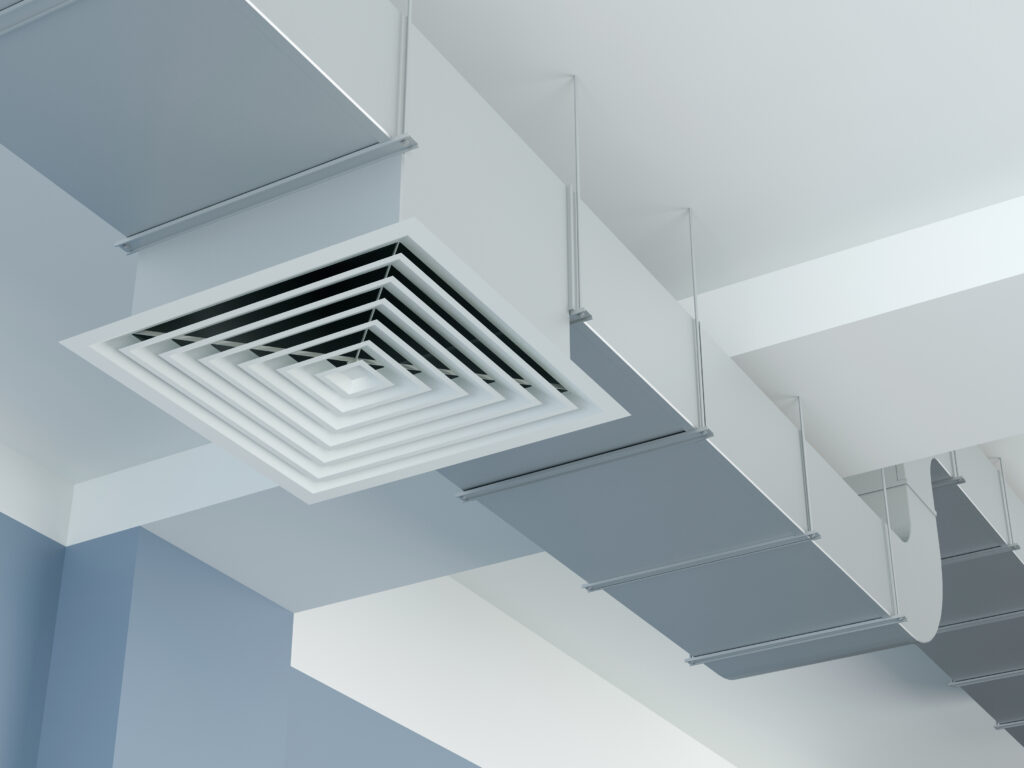

The supply air is distributed through a network of ducts or air distribution channels, and it enters individual rooms or spaces through diffusers, grilles, or registers. The air distribution is designed to ensure even and efficient delivery of conditioned air throughout the building.

The supply air is crucial in maintaining a comfortable and healthy indoor environment. It provides the necessary heating or cooling to achieve the desired temperature, helps control humidity levels, and ensures proper ventilation by introducing fresh outdoor air or recirculating conditioned air.

Monitoring and controlling the parameters of the supply air, such as temperature, humidity, airflow rate, and air quality, are essential for optimizing system performance, occupant comfort, energy efficiency, and indoor air quality.

Monitoring the supply air status for an HVAC (Heating, Ventilation, and Air Conditioning) system is essential for several reasons:

- System Efficiency: The supply air status provides valuable information about the performance and efficiency of the HVAC system. By monitoring parameters such as temperature, humidity, and airflow rate, you can ensure the system operates within the desired range. Deviations from the set points can indicate issues with equipment, ductwork, or control settings that may affect the system’s efficiency.

- Comfort and Indoor Air Quality (IAQ): Supply air monitoring helps maintain a comfortable and healthy indoor environment. By tracking temperature and humidity levels, you can ensure that the air delivered to occupied spaces meets the desired comfort criteria. Monitoring IAQ parameters such as carbon dioxide (CO2) levels or volatile organic compounds (VOCs) can help detect potential indoor air quality issues and take corrective actions.

- Equipment Performance and Maintenance: Monitoring supply air parameters allows for early detection of problems with HVAC equipment. Temperature, airflow, or pressure changes may indicate fan malfunction, filter clogging, or refrigerant leaks. Timely identification of such issues enables proactive maintenance and prevents equipment breakdowns or costly repairs.

- Energy Efficiency and Cost Savings: An efficient HVAC system helps minimize energy consumption and reduces operational costs. You can identify energy inefficiencies by monitoring supply air parameters, such as excessive cooling or heating, airflow imbalances, or inadequate ventilation. This information allows you to optimize system performance, adjust set points, or make necessary repairs to improve energy efficiency and save on utility bills.

- System Optimization and Control: Supply air monitoring data can be used to fine-tune and optimize HVAC system operation. By analyzing trends and patterns in the supply air parameters, you can identify opportunities for energy savings, implement demand-based control strategies, or optimize ventilation rates based on occupancy patterns. System Optimization and Control helps ensure that the HVAC system operates effectively and efficiently based on actual needs.

Source: iStock

There are several reasons why the supply air in an HVAC system may need optimization. Here are some common factors that can affect the quality or performance of the supply air:

- Equipment Malfunction: Issues with HVAC equipment can lead to suboptimal supply air. For example, a malfunctioning fan may not deliver the required airflow, a faulty temperature sensor could lead to inaccurate temperature control, or a clogged filter may restrict airflow and reduce air quality.

- Improper Maintenance: Inadequate or infrequent maintenance of HVAC components can impact the supply air quality. Dirty filters, coils, or ductwork can accumulate dust, debris, or microbial growth, reducing airflow, hindering heat transfer, and potentially introducing pollutants into the air stream.

- Ductwork Problems: Issues with the ductwork system can compromise the supply air. Leaks, cracks, or poor insulation can result in air leakage, causing pressure imbalances, reduced airflow to specific areas, and energy loss. Improperly sized or designed ducts can lead to inadequate air distribution and temperature variations.

- Incorrect Settings or Controls: Incorrect settings or faulty controls can affect the supply air parameters. If temperature, humidity, or ventilation controls lack proper calibration or malfunction, the supply air may not meet the desired conditions, leading to discomfort, poor indoor air quality, or energy wastage.

- Airflow Imbalances: Uneven airflow distribution can occur due to poor duct design, improper damper settings, or obstructions within the system. Areas farther from the air handling unit may receive insufficient airflow, resulting in temperature inconsistencies and reduced comfort.

- Inadequate Ventilation: Insufficient outdoor air intake or improper ventilation rates can affect the supply air quality. Inadequate ventilation may lead to elevated levels of carbon dioxide (CO2), volatile organic compounds (VOCs), or other indoor air pollutants, negatively impacting occupant health and comfort.

- Environmental Factors: External factors such as outdoor air pollution, allergens, or high humidity levels can impact the supply air quality. If the HVAC system doesn’t adequately filter or condition the outdoor air, these factors can be introduced into the supply air and affect indoor air quality.

It is essential to conduct regular maintenance, address equipment issues promptly, design and install ductwork correctly, calibrate and test controls, and monitor and adjust airflow and ventilation rates based on occupancy and outdoor conditions. Regular inspections, performance testing, and adherence to industry standards can help identify and rectify any issues affecting the supply air in an HVAC system.

In summary, monitoring the supply air status for an HVAC system provides valuable insights into system performance, comfort, indoor air quality, energy efficiency, and maintenance requirements. By continuously monitoring and analyzing this information, you can make informed decisions to optimize the system’s operation, reduce energy consumption, and enhance occupant comfort and well-being.

Let FSG Smart Buildings help you with monitoring your supply air. Contact us and find out how we can deliver success for your organization today.

Interested in building automation and helping customers build smarter buildings? Come work for us! FSG Smart Buildings is hiring talented people looking for a great career in building automation.

More from the Blog

Helping Make Circle K’s Continuous Lab a Reality

Helping Make Circle K’s Continuous Lab a Reality

Circle K‘s success in the convenience retailing industry spans over 60 years and has developed into a global chain. Facility…

The Benefits of EMS/BAS in a Convenience Store

The Benefits of EMS/BAS in a Convenience Store

The adoption of Building Automation Systems (BAS) or Energy Management Systems (EMS) technology in convenience stores can vary depending on…

The Many Benefits of Maintenance and Monitoring Programs

The Many Benefits of Maintenance and Monitoring Programs

A Building Automation System (BAS) or Energy Management System (EMS) maintenance and monitoring program refers to a comprehensive plan and…